Choosing Your Roller

Ashland Conveyor can offer many different replacement rollers in a variety of combinations with material, gauge, shaft size, and between frame dimension. Many of our rollers also have the opportunity for upgraded bearings and product options including the addition of vinyl or polyurethane sleeve. Although Ashland Conveyor cannot meet all roller configurations, we have multiple choices to fit your application.

Scroll through this replacement roller guide to learn about Ashland Conveyor's roller models and how to choose the right roller for your application.

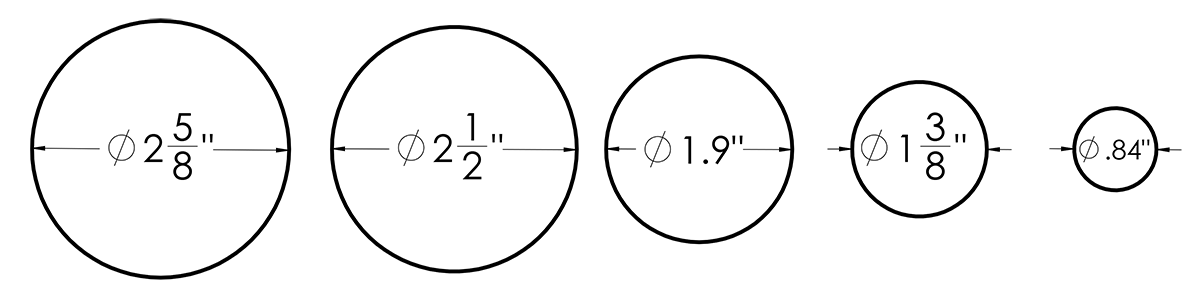

Diameters:

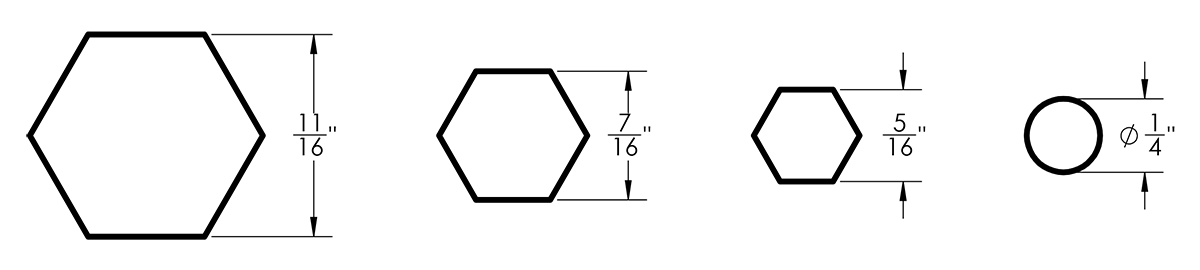

Shaft Sizes:

Material Options:

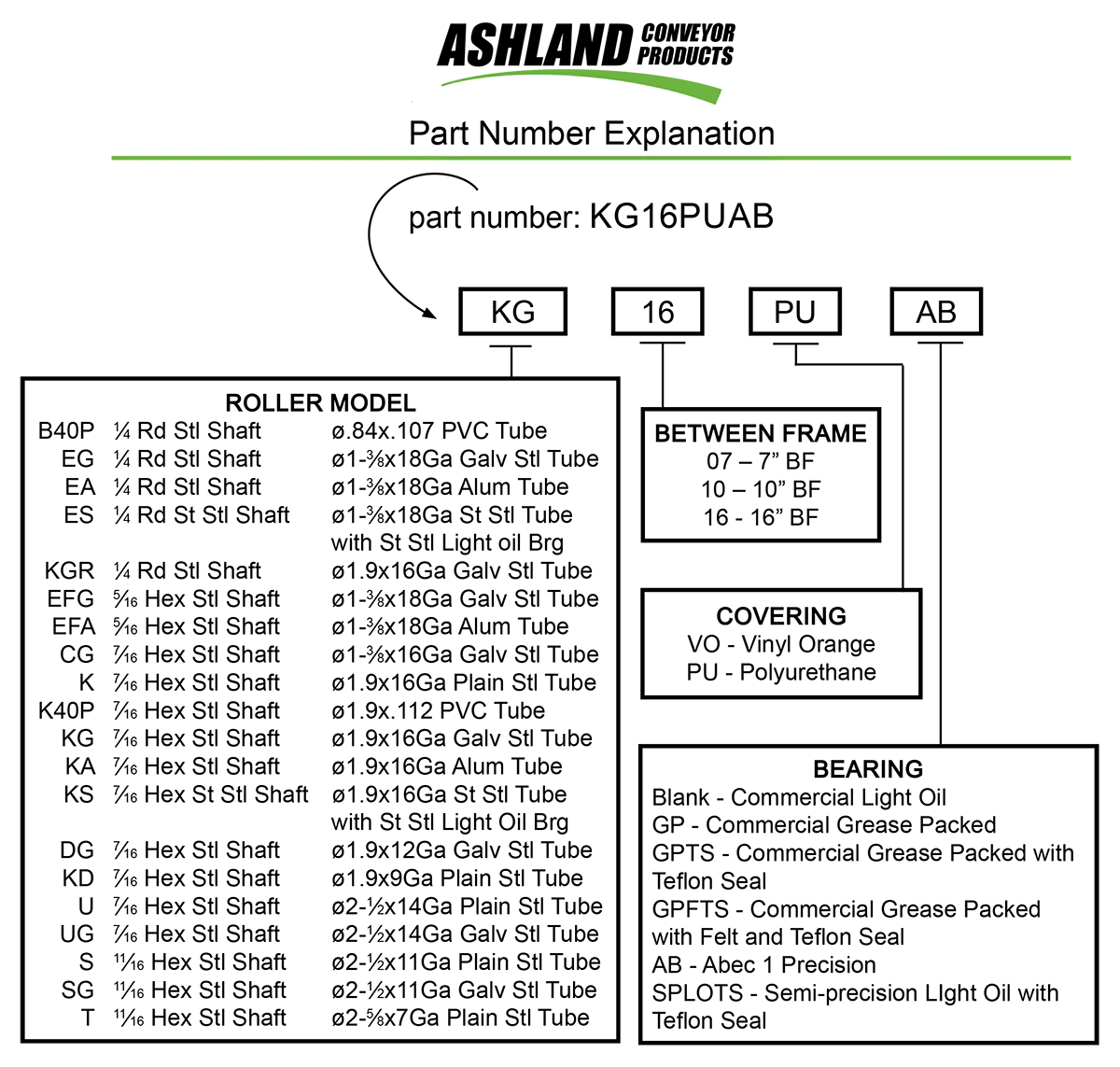

Our Roller Models

Ashland Conveyor's roller models are designated by an assortment of letters. Each letter combination correlates to tube diameter, gauge, and shaft size. Each letter combination will be followed by a number. This number is the between frame dimension of the roller.

Many of our rollers also have the option for an upgraded bearing or the addition of a vinyl or polyurethane sleeve which will be noted after the roller model and between frame dimension:

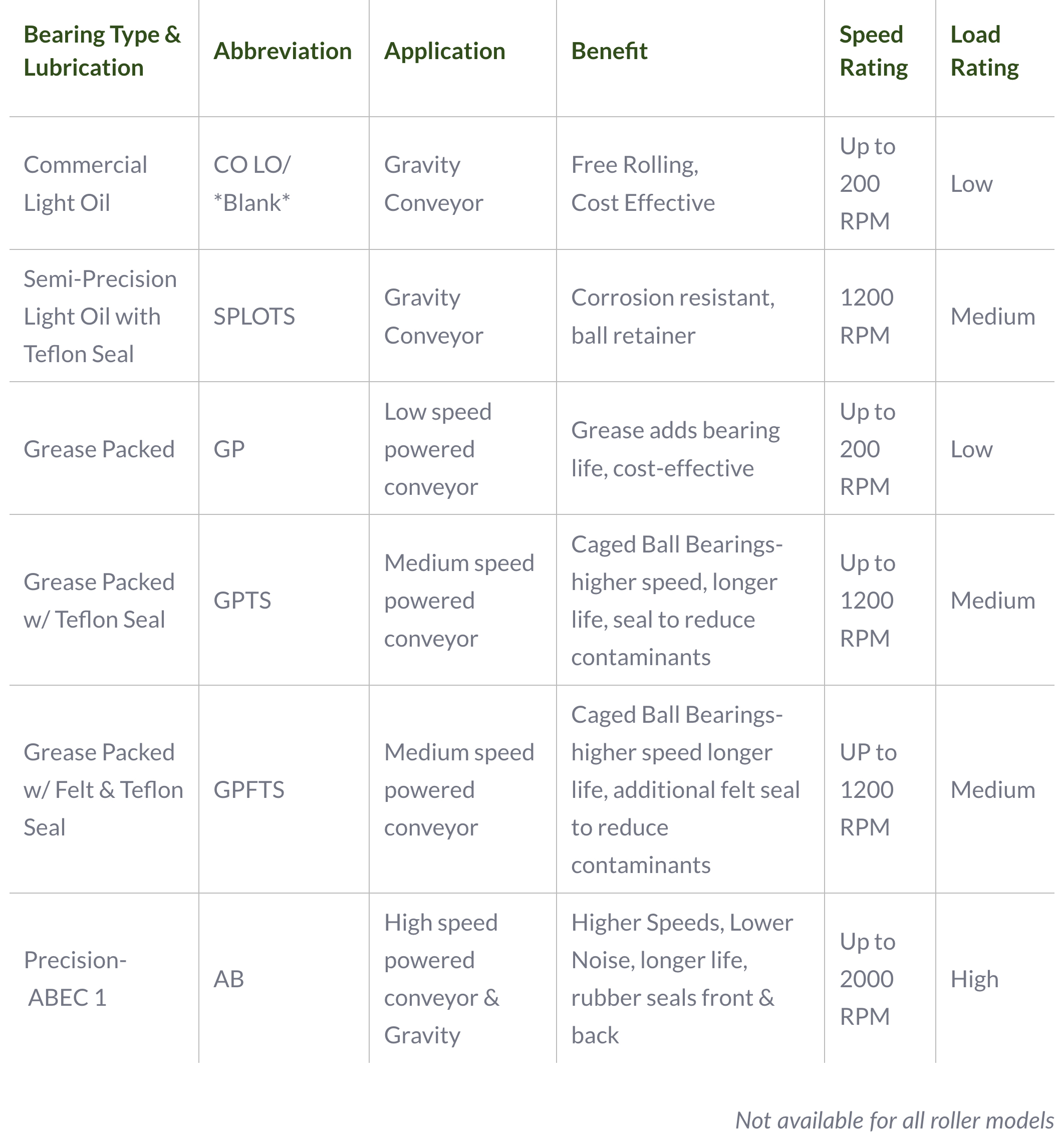

Bearings

Our standard roller construction utilizes "commercial grade" (also known as "non-precision") bearings. These standard bearings are made with a light oil lubrication that is generally used for gravity applications so that the rollers will rotate easily.

Grease packed bearings are normally used for power applications or harsh environments. The seals on the grease packed bearings refer to the materials that are used to impede particle (non-liquid) type items from entering the bearings.

The ABEC 1 bearings have significantly lower noise levels, longer life, higher capacity, and are usable in high powered applications. They also provide excellent concentricity.

Bearings can also be purchased separately, but are not interchangeable with an existing Ashland Conveyor roller as the bearings are crimped into the roller tube. To see our bearing options, click here.

Sleeve Options

Ashland Conveyor offers two different sleeve options for its rollers: polyurethane and vinyl. The sleeves are available on our galvanized steel and stainless steel rollers and come in the color orange.

Polyurethane Sleeve

- Factory installed 1/8" thick (83 Shore "A")

- Will not mare finish on sensitive products being conveyed

- Absorbs shock and reduces noise by up to 10 decibels

- Cut and abrasion resistance for long life

- Increases traction up to 15% vs non-coated rollers

Polyurethane Sleeve

- Factory installed 1/8" thick (83 Shore "A")

- Will not mare finish on sensitive products being conveyed

- Absorbs shock and reduces noise by up to 10 decibels

- Cut and abrasion resistance for long life

- Increases traction up to 15% vs non-coated rollers

Vinyl Sleeve

- Factory installed .050" thick (85 Shore "A") vinyl heat shrink sleeve

- Will not mare finish on products being conveyed

- Absorbs shock and reduces noise up to 10 decibels

- Operating temperature of -4 to 220 degrees Fahrenheit

- Increases traction

- Less expensive alternative to polyurethane covered rollers

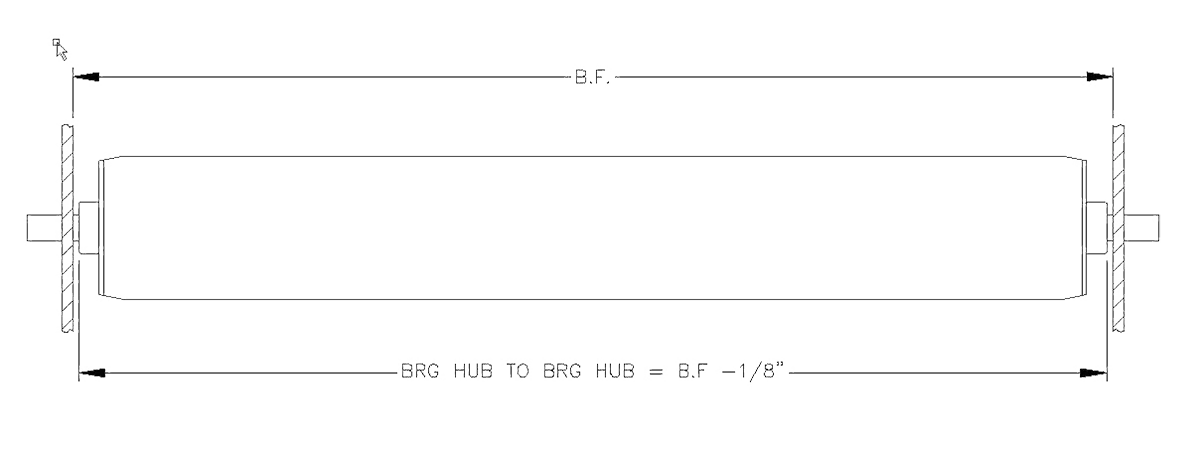

Between Frame Dimension (BF)

The length of our rollers is described in terms of the BF; the dimension between the frame, or rails, of the conveyor. To get this dimension, you will need to measure the distance from the inside of one rail, to the inside of the other rail on your conveyor. Between frame dimension is measured in inches.

The available BFs will be limited by the roller model due to capacity requirements.

Take a look at the drawing and photo below to learn how to measure this dimension: